Contents

- 1 Intro

- 2 II and III?

- 3 Drawing from magazine

- 4 Electrical drawings

- 5 Märklin 55681

- 6 My Märklin

- 7 Let it shine in the correct light

- 8 Remaining Krokodils

- 9 A crocodile exception?

- 10 Communities

- 11 The manual

- 12 Spare parts

- 13 Q&A

- 14 References

- 15 Comments

Started 09Feb2020, updated16Mar2025 (NSB EL 4. 13254 is on the move! Montaperti Modelltechnik , Spare parts. Italian FVB 11–14, Comms with Märklin. Fine Art update. Pesolillo on a YouTube movie. Verein «Krokodil 14305» [38], Hatches wrongly positioned. Pesolillo. Märklin 55688. «Fine Art Models», 55683 has got Dead Man’s Switch, Märklin 18045. «coupler» vs. «coupling» fixed. 55683 is new model!) This note has the character of a log from my dis5overy journey. It has a lot of unanswered questions, also for you. It is not a textbook!

Disclaimer, see Standard Disclaimer. This is also mentioned elsewhere here. It simply means that I don’t have ads and mention any company freely without expecting anything back. I kind of collect stuff, for myself and perhaps for you.

24Jan2023: SBB Historic has changed their web pages. Search for «SBB-new-web». On my desktop it still comes up in mobile view. The search page is athttps://www.sbbhistoric.ch/suche/?phrase=(no English).

In this note I will try to convey what I discover about the gauge 1 Märklin 55681 “Crocodile” locomotive, a model of the Ce 6/8 III with road number #14305, the original as owned and run by SBB Historic. This note is in subgroup My Crocodile locomotive pages of group MODELS. That’s the start. Then come the real locomotives!

If you find any errors or problems, please comment (below) or mail me!

Intro

The original locomotive in 1/1 is parked for next «fitnessfahrten» in Olten in Switzerland – the 1/32 scale 1 model is by me. And I guess, at several thousand other places.

I thought this started on vacation in Bologna in the summer of 2019, where the owner of the Märklin Shop opened a box, showing me this scale 1 model. My wife Mari took a picture of me, she also enjoyed the sight of it. And of me, being so enthusiastic, I guess.

However, thinking it over, it started with the oldest Märklin catalogue I still have. 1961/62 (I still think I have the 1959 catalogue somewhere). In that catalogue the HO Märklin 3015 model of the Ce 6/8 III cost 246 NOK and weighted 960 grams.

The new treasure I hold in may hands cost 35000 NOK. In many ways this loco has a life with me, as I suppose it would for any old boy starting off as a small boy with a twinkle in the eye for trains of any size.

The Crocodile also has a life with Märklin. I think it started already in 1930 catalogue [3]. But only now do I have one myself. I did not buy it on the web and took the work with importing it myself, I just went to the local dealer that I want to keep: Trønderfrim, here in Trondheim.

And no, it’s not bolted to the track, I tell those whom I show how to try to lift it. It just weights its ton of 6.5 kg. If it had been scaled down with everything in it I think it should have weighed 126.000 kg. / 32 / 32 / 32 = 3.85 kg. The model’s length is 62.6 cm. Multiplied up we have 62.6 * 32 = 2003,2 cm. The original is 2006.0 cm (according to the German Wikipedia page).

| German |

English |

||

| krokodil | krokodile | crocodile | crocodiles |

| Swiss jargon | |||

| kroki | krokis | .. | .. |

II and III?

Since this note is more like a log of discoveries, I start with what I have been most concerned about. What happened in 1925, when they designed the III models? My model. Story-wise I am pulling a thread, and much more than one answer fall out of the closet. So it’s a full in medias res start:

Fig.12 – SBB Ce 6/8 II vs. SBB Ce 6/8 III and SBB De 6/6 I. Märklin scale 1 55681, and HO 37511. Photo Øyvind Teig (Press for more pixels)

The figure will be described in the following. See the small brown loco lower, left? It’s the much smaller Seetal-crocodile SBB De 6/6 (also when scales compare!) which does not have pilot/leading trucks/wheels, ie. no end axle without drive. The drive construction was tested out on two sister locos (search for «sister» here), then taken to the Ce 6/8 III-version. Don’t confuse the 14.0 m long SBB De 6/6 (here) with Rhätische Bahn RhB Ge 6/6 I, which is 13.3 m long and runs on 1000 mm meterspur narrow gauge (here)).

This is also much described at www.lokifahrer.ch by Bruno Lämmli (at 203[08] but also here).

Inclined driving rod

One of my intentions with this note was to find out why the engineers around 1925, when they designed the III-version, decided to move the jackshaft (Wiki-refs) (NO: «blindaksel») from ending at the nearby front/rear wheels to crossing a wheel to end at the third wheel. See Fig.12 (above), and more later. (The top connection of the jackshaft is a rather large box. I think this contains a rocker arm (Wiki-refs), introduced to get some flexibility there and get less vibrations (Moser and Pfeiffer @ [2] p.16). I learn that even with all this steel, flexibility is needed on all kinds of strange places).

Preempting about the driving mechanism with this explanation «The two motors in each nose unit were geared to a jackshaft between the drive axles farthest from the cab, with side rods carrying the power to the drivers.» (Wiki-refs: Crocodile). Since this was rather unprecise I edited the text on 17Mar2020 to : «The two motors in each nose unit were geared to a jackshaft between the drive axles farthest from the cab (SBB Ce 6/8 II) or farthest from the end (SBB Ce 6/8 III), with side rods carrying the power to the drivers.»

This tells about the result of the design. If the jackshaft had not been moved I would have been happy. But now, I want to understand what happened.

Fig.11 Download the screen clip PDF here

The text by Andreas Steimel, [14] p.38 goes like this:

During the Great War, gearings of 1 MW rating became possible. Fig. 3.5 shows the Winterthur «inclined driving rod» system with primary gear transmission, which was developed by the Swiss Locomotive Factory (SLM) of Winterthur in 1922 for the 2nd series of «Krokodil»- type locomotives.

Two drive motors provide torque via a primary gear transmission of about 1:3 to (*) an intermediate driving axle which is mounted slightly higher than the driving wheelsets. It drives the outer drive wheelset via slightly inclined oblige driving rods, the inner wheelsets being driven by coupling rods from the outer sets. This system was used for slow locomotives of high tractive force until the 1960s; for example, the heavy «Dm» locomotives of the Lulea-Kiruna-Narvik iron-ore railway where equipped with this kind of drive.

(*) Ce 6/8 has a different ratio (later). Winterthur «inclined driving rod» system is «Winterthurer Schrägstangenantrieb» in German. Puh! It took me days to get that term. Even if «schräg» means «inclined» or «slanted». I had Google translate the German Wikipedia article SBB Ee 6/6 for me. In that translation I discovered the phrase for the first time. Then I found the Steimel reference (above). However, if I let Google do it only on «Winterthurer Schrägstangenantrieb» I get «Winterthur diagonal drive» which gets the meaning, but I assume – is not the technically used term in English(?)

However, to me both the II-version and the III-version‘s driving rods look rather inclined. Why call only the III-version inclined?

Then I found the German Wikipedia Stangeantrieb (Wiki-refs) article, which tells about everything. The Winterthur-Schrägstangenantrieb chapter (based on Google’s translation) goes like this (13Mar2020) (All German links):

| Winterthur-Schrägstangenantrieb

Der Winterthur-Schrägstangenantrieb oder Winterthurer Schrägstangenantrieb ist ein im Aufbau einfacher Antrieb. Die Basis des Antriebs ist eine leicht nach oben versetzte Vorgelegewelle. Diese treibt eine einfache Treibstange an, die mit einer dreieckförmigen Kuppelstange verbunden ist. Die gesamte Geometrie des Antriebes kann vertikal in einer Ebene angelegt werden. Durch die Anordnung in einer Ebene ergibt sich aber, dass die Treibstangen nicht an den Kurbelzapfen des primären Treibradsatzes angelenkt werden können, sondern exzentrisch an den dreieckförmig ausgebildeten Kuppelstangen, was zu zusätzlichen mechanischen Beanspruchungen der Kuppelstange und der Kurbelzapfen der durch die Kuppelstange angetriebenen Radsätze führt. Dies manifestiert sich geräuschmäßig durch ein Knacken in den Wendepunkten. Nichtsdestotrotz war der Antrieb seiner Einfachheit wegen der meistverbreitete Stangenantrieb für elektrische Lokomotiven. Ein sehr frühes Beispiel war die BLS Ce 6/6 121, ein Einzelstück, aus dem Jahre 1910. Sie hatte eine für damalige Verhältnisse sehr hohe installierten Leistung von 1470 kW (2000 PS). Weitere Beispiele sind SBB Ce 6/8I, SBB Ce 6/8III, verschiedene SBB Ee 3/3, RhB Ge 6/6I oder DR-Baureihe E 91. |

Winterthur inclined driving rod

The Winterthur diagonal bar drive is a simple drive in construction. The basis of the drive is a countershaft that is slightly shifted upwards. This drives a simple drive rod, which is connected to a triangular coupling rod. The entire geometry of the drive can be created vertically in one plane. However, the arrangement in one plane means that the drive rods cannot be articulated on the crankpin of the primary drive wheel set, but eccentrically on the triangular coupling rods, which leads to additional mechanical stresses on the coupling rod and the crankpin of the wheel sets driven by the coupling rod. This manifests itself in noise by a crack in the turning points. Nevertheless, because of its simplicity, it became the most common rod drive for electric locomotives. A very early example was the BLS Ce 6/6 121, a one-off, from 1910. It had a very high installed output of 1470 kW (2000 hp) for the time. Other examples are SBB Ce 6/8 I, SBB Ce 6/8 III, various SBB Ee 3/3, RhB Ge 6/6 I or DR series E 91. |

What does the article mean with the part mentioning «vertically in one plane» and «articulated on the crankpin»? Time off for a picture:

Here is another description of the II to III transition. From [2], page 44-45 (the next three tables).

Update 26Jul2021: Observe that it’s the single test locomotive SBB Ce 6/8 I #14201 (here) where the diagonal drive was first used. This was before the SBB Ce 6/8 II, albeit with 2/1 instead of 1/2 axles per frame. So then, whe didn’t they reuse that scheme for the SBB Ce 6/8 II? The other sister test locomotives Be 3/5 12201, Be 4/6 12301 and Be 4/6 12302 did not have two frames with three axles each, that’s one difference. To test the same axle placement they made the Seetal crocodile SBB Ce 6/6, maybe to confirm the I scheme and also not follow the II scheme (here, plus the small one in Fig.12).

| Schrägstangenantrieb

In der ersten Hälfte der 1920er Jahre waren die vier 1919 abgelieferten Probelokomotiven der Typen Be 3/5, Be 4/6 und Ce 6/8 I umfassend getestet worden. Die Ce 6/8 I Nr. 14201 verfügte über den von der SLM neu konstruierten Winterthurer SchrägstangenAntrieb. Er war gegenüber den bei den Ce 6/8 II verwendeten Triebwerken mit dreieckigen Kuppelrahmen und Blindwellen weniger aufwändig und hatte sich in der Zwischenzeit auch bei der Prototyp-Lokomotive Ce 6/6 Nr. 121 der BLS, den Ge 6/6 I der Rhätischen Bahn und bei verschiedenen ausländischen Triebfahrzeugen bewährt. |

Winterthur inclined driving rod

In the first half of the 1920s, the four Be 3/5, Be 4/6 and Ce 6/8 I test locomotives delivered in 1919 had been extensively tested. Ce 6/8 I No. 14201 was equipped with the Winterthur diagonal bar drive newly designed by the SLM. It was less labour-intensive than the engines with the triangular |

I always have to look over Goolge translate. It seems like aufwändig translates neither to expensive nor complex (as suggested by Google) but to something closer to workload or effort. However, labour-intensive probably covers best what the authors have meant (thanks, son Andreas!). And Kuppelrahmen is not dome frame but coupling frames. Thomas Ruch (later) adds that the design effort (also difficult translation from aufwand) was less with the new scheme. And we saw that the Stangeantrieb article (above) talked about simplicity. So there must be something about the need for the counterweight on the II-version and the complexity with it that they really wanted to get rid of. The magazine article in [2] continues:

| Diese Antriebsart funktioniert wie folgt: Die von den Fahrmotoren über Ritzel angetriebene Vorgelegewelle ist zwischen der ersten und zweiten Treibachse platziert. Sie ist mit einer Schrägstange gekuppelt, die die Kraft auf die dritte Antriebsachse überträgt. Hier wirkt sie auf einen Kurbelzapfen, derauf der von der dritten zur zweiten Antriebsachse führenden Kuppelstange sitzt. Von dort leitet eine zusätzliche Kuppelstange die Bewegung an die erste Treibachse weiter. | This type of drive works as follows: The countershaft driven by the drive motors via pinions (gears) is placed between the first and second drive axles. It is coupled with an inclined bar that transfers the force to the third drive axle. Here it acts on a crankpin that sits on the coupling rod leading from the third to the second drive axle. From there, an additional coupling rod transfers the movement to the first drive axle. |

Even if they had tested this mechanism in several locomotives, I think only one of the tested had the design of a crocodile (with two major joints connecting the middle box with the two drive frames), the Ge 6/6 I, see Wiki-refs. (They also tested other matters, like end gears and helical gears for the motors, I assume, also with respect to vibrations ([2] p.16)). My Seetal Crocodile is about the same type (SBB De 6/6 I, seen in Fig.12 (above, lower left)), but it was a little newer. Despite all this testing there were «undesirable vibrations«. Thomas Ruch uses the words «self-resonance» and «lulling» (later). Continuing:

| Derfür die Ce 6/8 III gewählte Antrieb lässt bei schlechter Gleislage und bei Schienenstößen unliebsame Schwingungen entstehen. Sie können in extremen Fällen zu Materialermüdungen, Rissen oder Brüchen der Schrägstangen führen.

Dies ist auch der Hauptgrund, dass er sich nurfür Lokomotiven mit Fahrgeschwindigkeiten von maximal 70 bis 75 km/h eignet. Da die Krokodil-Lokomotiven unterhalb dieser Tempolimite betrieben wurden, galt diese Einschränkung nicht als Nachteil. Entsprechend kam dieses Antriebskonzept auch bei den Seetal-Krokodilen De 6/6 Nr. 15301 bis 15303 (Inbetriebnahme 1926) sowie bei den Rangierlokomotiven der Typen Ee 3/3 und Ee 6/6 (Baujahre 1928 bis 1956) zur Anwendung. |

The drive selected for the Ce 6/8 III creates undesirable vibrations when the track is bad and when the rails are pushed. In extreme cases, they can cause material fatigue, cracks or breaks in the diagonal bars.

This is also the main reason that it is only suitable for locomotives with a maximum speed of 70 to 75 km/h. Since the crocodile locomotives were operated below these speed limits, this restriction was not considered a disadvantage. Accordingly, this drive concept was also used for the Seetal crocodiles De 6/6 No. 15301 to 15303 (commissioned in 1926) and for the shunting locomotives of the types Ee 3/3 and Ee 6/6 (years of construction 1928 to 1956). |

They had got a problem with 18 machines, but this was considered a trait more than a misdesign. It was ok enough, even if they had more(?) breakages. But then, Thomas Ruch says below that they were quite «smooth» at 50 km/h. And SBB were still able to transform them to higher speed from Ce to Be. However, they did that with both the II and the III types.

Update 6Jul2021: More on balancing and hammering (from Wikipedia Coupling rod chapter Balancing. It refers to Hammer blow (hammering). I think this is the force that came with the III types that caused this vibration, even it the quote below is about steam locos(?):

The vertical component of the vibration that could not be eliminated because of the weight needed to balance the pistons is called hammering. This is destructive to both the locomotive and the roadbed. In some locomotives, this hammering can be so intense that at speed, the drivers alternately jump from the rail head, then slam down hard on the rails as the wheels complete their rotation. Unfortunately, hammering is inherent to conventional two-cylinder piston-driven steam locomotives and that is one of the several reasons they have been retired from service.

Aside: I show the German texts here, as well as well as the Google translated versions, with respect of the original wording. But I do recommend to buy the magazine. It is a joy to have!

It is starting to dawn on me that this design became the standard. It’s the II-version that’s special! But it was only the crocodiles that were articulated (they twist when they turn). Maybe the vibrations were not present in the single frame type machines? All up to 1952 the SBB Ee 6/6 (German) was designed with this inclined driving rod construction. And as Steimer mentioned, almost like this, is the Dm locomotives at Luleå-Kiruna-Narvik – in 1954. Update 5Jul2021: a Swede told me that the DM locos were built up to 1971, since locos with coupling rods would not slip on individual axles. This was important for ore traffic. Thanks, Rolf Nord!

I must have some kind of attraction to this design. When I look over my HO collection, I have several locos with it! All built after SLM designed it in 1922:

- SBB De 6/6 «Seetal crocodile» #15302, Märklin 37511. See a better photo at 216:[Märklin 37511 of the SBB De 6/6 Seetal crocodile]

- BR 160 E 60 09, Märklin 37561

- BR 191 101-5, Märklin 37294 and blog note My Märklin 37294 DB Class 191 electric locomotive

- EL 10 254, Märklin 36336 (Norwegian EL 10, based on Swedish Ub by ASEA, based on SBB Ee 3/3 I assume)

- BLS Te 2/3 nr. 3. See blog note My BRAWA 0571 BLS Te 2/3

- SBB Ae 3/6 II is also in the same family, I assume. See blog notes Models. This model started my interest of Swiss electric locomotives! I have some of them. I was hoping to find a scale 1 (or 1/45) model of it that I could afford, since I had seen several «live». I didn’t. But Märklin came to the rescue with the Ce 6/8 III, this model 55681. If Märklin were to make a scale 1 of the Ae 3/6 II I would get more than one problem!

Thomas Ruch’s explanation

The included DVD with the magazine [1] explains some of the difference between II-version and III-version. I photographed the screen (screen copy was not allowed) from this fascinating DVD. Thanks to VGB! Here is a transcription of some of Lokführer Thomas Ruch‘s description in, Swiss German, in Teil 2, Normalspur, starting at 1.05.50 (I pasted the German (thanks, son Andreas!) into Google translate, here. The English is based on it):

| ..ist eine aufwendige sache. Ist eine reine blindwelle, die dient nur dem massenausgleich, und der massenausgleich funktioniert. Es gibt fast keinen stangenlok, der mit 50 ruhiger läuft wie die hier. Das ist aber mit einem gewissen konstruktiven aufwand verbunden. Bei der nachfolgeserie wurde der konstruktive aufwand gesenkt. Es gab dann eine direkte stange hier vom antriebauf die hinterste triebachse, nacher wieder nach vorne – aber sie lief nicht mehr so ruhig. Das ganze kam (..) so wie in eine eigenresonanz, und im nachtdienst muss es ziemlich einlullend gewesen sein. Das hier ist die dreiecksstange, daher auch der antrieb dreieckstangenantrieb. Die moteren arbeiten auf diese welle hier. Die da hier ist ohne antrieb, und dient nur den massenausgleich. |

..is an elaborate thing. Is a pure blind wave that only serves the mass balance, and the mass balance works. There is almost no rod locomotive that runs more smoothly at 50 than the one here. However, this involves a certain amount of constructive effort. In the successor series, the design effort was reduced. There was then a direct rod from the drive to the rearmost drive axle, then back to the front – but it was not as smooth. The whole thing came (…) as if it were a self-resonance, and it must have been quite lulling in the night shift. This is the triangular rod, hence the triangular rod drive. The motors work on this shaft here. The one there is without drive, and only serves to balance the masses. |

Ruch here seems to confirm what we also saw before this quote (but it was that DVD that caused me to research more and buy [2]) – that the new design of the III-version was wobbling. But how are the running properties of the previous II-version locomotives?

II and III-type versions

These are only scale 1 models (not H0/HO, N, Z or other scales):

Märklin

First, have a look at the Märklin Product database [20] and have search or two there. (Thanks to Jeroen Schrage (NL), for this tip. It caused me to add more models in the list below.) And [21] even shows the first scale 1 (gauge 1) CCS 66 12921 scanned from the 1934 catalogue. In [22] the original 20V AC motor and reversing mechanism are also explained. Update Jan2023: also, have a look at [36] by SBB (2022).

This list originally started out from German eBay (here). Later on the references above were also used. I don’t pretend to make this a complete list, since this is not actually what this note is about. But the one took the other. Listed by product number, largest on top:

- 55688 – Ce 6/8 II is a version lettered for the New York Central Lines (NYCL). See 55565 (below). Available only in the «märklineum» shop in Göppingen. Presented in «Special Imprint and Special Products and Summer New Items 2024». It’s white: 55688

- 55686 – Ce 6/8 III with «unusual, fictitious paint scheme, based on a steam locomotive». One-time series. It’s even got a fictitious road number: 2019.

Available only in the «märklineum» shop in Göppingen.Update Nov2020: I also saw it available in a shop, like Modellbahnshop-Lippe. It’s green with red wheels: 55686 - 55683 – Ce 6/8 III with road number 14311 (brown), see 55683 (Presented in Summer New Items 2023 and Full Line 2023/2024 p316). I have tried to assemble the differences between this and the 55681 in a PDF here. It has even got the Dead Man’s Switch («Pedal» as used in this note) in place! See märklin-users.net point 9.

- 55681 – Ce 6/8 III with road number 14305, revision

02.11.17, done in Meiningen (green): 55681. It’s in the full line catalogue 2019/2020 p. 351-353. It has sound and also remote control of the pantographs. My locomotive - 55567 – Ce 6/8 II with road number 14281 (Brown version with authentic traces of snow): 55567. One-time series (2016?)

- 55565 – Ce 6/8 II (thanks Michiel Hooijberg for pointing out that it’s based on II (in comment below)), 55565. White version lettered for the New York Central Lines (NYCL), based on a hand sample produced as a single item by Märklin in the thirties for the USA(?) Märklin’s 150 years anniversary 1859-2009. Summer New Items 2009 – Product programme 2009/2010

- 55564 – Ce 6/8 II with road number 14281, revision

27.5.29(brown): 55564. It’s in the full line catalogue 2013/2014 pp. 390-391. It has sound, but the pantographs are hand raised only - 55563 – Ce 6/8 II with road number 14272 (green): 55563. New items 2009 and full line catalogues 2009, 2010. One-time series celebrating Märklin’s 150 years anniversary 1859-2009

- 55562 – Ce 6/8 II with road number 14268 (brown): 55562. New items and full line catalogues, 2006

- 55561 – Ce 6/8 II with road number 13256 (green): 55561. Crocodile Limited Edition 100 years – SBB-CFF. Product programme 2001 / 2002

- 5758 – Ce 6/8 II with road number 13253 (green): Märklin 5758 (1984, series of 3300) (revision

24.12?.47). Plastic housing. Märklin 125 years anniversary 1859-1984 - 5757 – Ce 6/8 II with road number 14253 (brown): Märklin 5757 (1984, series of 3300) (revision

28.9.82). Plastic housing [19] - There also are a lot of older, analog models, like

- 5756 – Ce 6/8 II with road number 13254 (green): Märklin 5756 (revision

24.4.76) - 5736 – Ce 6/8 II with road number 13254 (green): Märklin 5736. Same as above?

- …

- CCS 66 12921 in the 1934 catalog, see et at [21]

- 5756 – Ce 6/8 II with road number 13254 (green): Märklin 5756 (revision

- Märklin 18045. Quoting from Crocodile Replika: «The model of the crocodile in H0 was originally planned as early as 1936 and was to be launched on the market under item number CCS 700. However, it remained a prototype – not least due to the circumstances of the time. It was not until 1947 that an H0 model of the crocodile was presented under the number CCS 800 – the later 3015. This is the first edition of the first Crocodile prototype ever produced by Märklin for the H0 gauge from 1936.» (30dec2023)

Other brands

- Modelbex Spur 1: SBB Ce 6/8 III #14301 (Art. Nr.: I-MX.004/1A-Modelbex). The Modelbex models are of metal, brass only (no die-cast zinc) [19]. Both from Era II (1925-1945). They don’t have the Integra-Signum magnets mounted, so the revision must be some time before 1933(?) They have sound, but I don’t think they can raise the pantographs remotely.

- Modelbex Spur 1: SBB Ce 6/8 III #14304 (Art. Nr.: I-MX.004/1B-Modelbex)

- Lemaco Brass Gauge I Model SBB Ce 6/8 III (about 1990) [19]

- In Michiel Hooijberg‘s comment (below), there is a url to his fantastic list of Crocodile models

- Fine Models made a scale 1 version of the SBB Ce(Be) 6/8 II Krokodil, #13254 green, #14254 brown. On the Internet Archive’s Wayback Engine it’s seen first in Dec. 2012, also showing that it was sold for €6500 (here). It also shows that Fine Models was started on 1Jan2003.

- An American company called Fine Art Models (FAM) in 1995/1996 produced two series of 50 in each of very detailed scale 1 models of the SBB Crocodile Be 6/8 II, see [37]. These models are analogue, but still have extensive sound, recorded from #14253. I think the loco is driven with an optional controller called a «throttle power pack», which takes 12V DC as input. (In a mail with a person who has experience with these models I learn that they have two motors and that these motors not necessarily run well as a pair, and that those locos probably excel best in a display case. He also told that SJ Models in Korea produced the crocodile models for FAM). FAM delivered a lot of models, like #14254 (brown) and early version and late versions of #14282 (green) and #13254 (green) plus #14253 (green and brown). FAM says on their page that «Fine Art Models’ objective in building this model was to establish a new standard, not only for the Crocodile, but all locomotive models moving forward.» Plus: «We began the design process for our Crocodile by acquiring the builder’s plans from the SBB. We made a special trip to the Auto and Technik Museum e.v. in Sinsheim, Germany, to take more than 3,000 photographs, both inside and out, of every detail of the Crocodile 14282. As a result, our model is an exact replica of the prototype – every door, hatch and window that opens on the prototype also opens on our model. And what is seen behind these doors and hatches in the prototype is also seen in our model (even the locking doors on the battery boxes on the prototype lock on our model with a miniature key, supplied with each model).» Any reference to «fine scale» I think means that the wheels are wider than the NEM standard, and that it has nothing to do with the details being more fine scaled. Update: However, «Fine Art had a lot of fancy details or details that did not even correspond to the reproduction periods, for example the green one had Bavarian buffers mounted on it, which were never used in Switzerland«. (Quote from a mail, I have not been able to verify this myself)

- Pesolillo is coming (in 2025) with scale 1 models of the Ce 6/8 II and Be 6/8 II. These will come with hinged ventilation frames so that the internals like motors and switches are seen. Also the mains transformer is seen on the roof (etc.). This probably will surpass even the Fine Art Models model (above). See http://pesolillo.ch and spur1info 27.6.2024 (paid). A brass model was displayed on the Spur 1 Messe at Lokpark Ampflwang in Austria in June 2024. The raw brass model is for the first time presented in a talk with Peter Pernsteiner by Claudio Pesolillo at 1:32-Krokodil-Handmuster Ce/Be 6/8 II von Pesolillo – Interview Spur1-Messe Lokpark Ampflwang 6/2024 (YouTube). Also see photos on 203:[Pesolillo]. Also according to Spur1Info (11Oct2024) about the Italian class E.428, at least that model is manufactured in Korea

The Crocodile name

Fig.2 – 1/32 Märklin 55681 SBB Ce 6/8 III + Welly 9731 MB A-Class. Photo: Øyvind Teig (press for more pixels)

I think that it was Märklin who actually gave the locomotive this «crocodile» name when they made their first model of it, around 1930.

It looks like the train driver parked his short and tall Mercedes-Benz A-Class model from 1999 before he started the locomotive. Little Linnéa found it on a shelf when she slept over, and sensed that this was interesting for me. I had given it to Isac several years ago, but it was kept here. The car model is a Welly, a duplicate of this model.

Aside: The light sources I used for the photo made the colours also somewhat dream-like, and non of the different tools I had could fix it. iA on my Panasonic Lumix DMC-TZ100 camera produced fine colours, but the shutter was about 3. Not in focus all over. So I chose this picture shot in A (aperture) with an f of 8, which almost means pinhole camera with eternal depth.

There is a nice video presentation of the 55681 at YouTube by Peter Pernsteiner [7].

Drawing from magazine

Fig.2b Fig.2b – The II-end is at the left. From Eisenbahn-Romantik, 4.2019, page 42 by VGB Verlagsgruppe Bahn GmbH «Schweizer Krokodil» by Hendrik Bloem. Download PDF (4 MB, here) and JPG (4096, 900). Scanned from magazine and published here by permission from VGB Verlagsgruppe Bahn GmbH, 9Feb2020

I have actually found no sectional drawings of the Ce 6/8 II or III on the web. This drawing is from [1]. Thanks to VGB! I have not translated the German text. However, in [2] there would be even some cross sectional drawings, on two double pages.

Aside: I scanned as 1200 dpi and filtered some, then made a searchable PDF in ABBYY FineReaderExpress. But I found no font that had it convert Bloem correctly (it was always ‘i’ instead of the ‘l’), so imported that PDF into Pages and wrote the boxed text there (plus fixed 50/3 to 16⅔ instead of 16,7 Hz or 16.7 Hz (*)) and exported as PDF. It is still searchable. I also converted that PDF to 4096 and 900 pixels JPG. (*) 16.7 Hz is correct after 1995 (see Wikipedia’s 15 kV AC railway electrification) – so my change may have been wrong!

Electrical drawings

I have now bought a scan of the two best circuit diagrams (Schaltplan) that SBB Historic has. They are as nice that I could cry! See SBB Historic: Schaltplan – two circuit diagrams of the Ce 6/8 III crocodile.

Märklin 55681

This is a beautiful and very well designed and produced model. A joy to own! I enjoy every second! The label underneath says märklin 19045206 C€. Plus there is the märklin which is part of the metal frame.

Handling

How to lift it

As mentioned, it’s not bolted to the track. It just weighs its ton of 6.5 kg. The manual tells how to lift the model from the track [8]: «Please note that the roof is only sitting in place and is held by magnets. Do not hold the locomotive by the roof!» So it should be lifted with two hands across each end frame. See figure.Not upside down with roof in place!

BE EXTREMELY CAREFUL OR REMOVE THE ROOF!I was very unwise and wanted to have a curious look underneath – without thinking! The roof fell off! Luckily for me it hit the wooden floor from a low height, softly, and only a corner mesh fell off. It was easy to put back in place, there were three holes and pins. I also added a tiny drop of glue. Not visible from any angle, not even with the root off. The wire and connector were also pulled out, but nothing bad happened! I made the picture from several pages in the manual [8]. Press for a PDF to print out.

Disclaimer: (Not that it matters, since the roof did fall off). I may have been very unlucky and pushed the roof by accidence, in some way that I am not able to (or want to) reproduce. It may be that Märklin indeed has selected strong enough magnets, technically speaking. I tried to lift the roof with a luggage scale. It came off around some 500 g lift, on each side. 1 kg for both. The magnets also hold some after they slip. The weight of the roof is about 540 g. So it should be enough! Anyway, remove the top! It’s best in the long run!

How I carry it

However, even carrying the loco like that for two meters is tough on the fingers. So I made a veneer base and screwed a 60 cm track on it. And after the topmost picture was shot I made it thinner and easier to grip at the ends. Also good for the first lift off the table. The base that came in the box is probably not too well suitable for this.

Upside down on the workbench

Attention: If you have placed an extra driver inside cabin II, observe that he may fall out! Mine (here) actually stayed in his bindings, and the plate he’s mounted on didn’t move either.

I always keep everything that passes by, of the type of styrofoam that doesn’t disintegrate by a pinch; the type where nothing would fall off. Before the woollen seat pads, that plastic, you know. It’s expensive to buy, and for the environment it’s better to reuse than to have the factories produce more of the nice and terrible stuff. When my box gets full, only then do I return as plastic waste, the smallest pieces, or those that are glued the most. It was in that box that I found the material for different bases I needed for my upside down 55681 exercise. (By the way, this is also nice for turning HO/H0 locomotives upside down. Just make a kind of negative imprint of the loco box and cut out more for the delicate parts.) (Some more on materials here: My materials science notes.)

First, read all the words here. Only then start to lift things.

Second, make two bases for the roof. And find a small pair of pliers.

Then lift the roof off by pressing the fingers against the motor side tops, and up. It takes some pressing before the four magnets let go. Then hold the roof with one hand and use the pair of pliers to carefully loosen the servo cable’s connector. I found it easiest to loosen the part in the locomotive.

Check that all four magnets are still in the center box in the locomotive. If not, see «Some loose parts» (below).

Then make four styrofoam pieces for the body and two thinner ones for the center box. They should have some height comparison with each other, of course. Place them on the table, apart, to avoid placing the yellow signs on them. Then psyche yourself up, because you need two hands that takes a twist. Lift and twist. Then carefully place the loco down on the six styrofoam bases. I guess that’s about it.

Aside: don’t loosen the center box! I wanted to find out whether I could loosen the center box, so that I later could fit the driver in direction II (see Driver in direction II and a ground personnel) by letting the driver’s cab open from the top. Don’t even think about it, if that is the only thing you want! I think each and every screw underneath, not only the four recessed screws, would need to be loosened. And then you would get the problem of dismantling the handles by the steps, not a good idea. Not alone push them in again. Again see «Some loose parts» (below). Let them be like they are. Besides, I found a much better solution to placing my driver inside the empty cab. Again, it’s in Driver in direction II and a ground personnel).

Fig.38 – All the six wheels are loose in «suspension chambers» (no sound)

When we spend so much money on a single piece, it’s only natural to be curious and to turn it upside down, just to enjoy. Most of it is metal, but there certainly also are plastic parts. So, be careful. Now, run the movie and enjoy the nice suspension!

Update 26Jul2021: I have learned from the magazine Faszination Spur 1 #17 where Peter Pernsteiner goes through the Märklin 55526 of SBB Ce 6/8 I #14201 (here) that some times plastic is considered a better choice. On that locomotive the extensive cooling tubes along the sides are made of plastic since making them from metal would faster have worn the sides and made them not so nice, for the view of them. Fair enough!

Crash to safety?

I experienced a CRASH on my shelf! Believe it or not! Here’s what happened. I got excited and turned the accelerator up, with a plan to enjoy the squealing noise from the brakes. Playing like a child, that is. Blush. (But that squealing does have at least three CV registers: 64, 163 and 164, plus the f9 function. But that’s for more adult children. Unblush). All of a sudden I saw that the loco did not obey my stop command! Then I discovered that the MS2 (Mobile Station 2) was restarting! The loco went straight into the rail buffer and continued with rotating wheels on the dry rail! Terrible! Finally I got contact with it, and it decided to stop pushing against the Märklin 5602 buffer. But luckily, everything survived – with no new pieces and no spare pieces to order!

First, I should have used the central, round RED BUTTON that changes direction, in order TO STOP. The built-in power capacitor (called a voltage buffer in the manual [11], but this is an electric charge buffer) (set by registers to be connected) causes the loco not to obey the standard, wide STOP STOP button. The loco simply runs on over bumps and dips of no voltage on the line, so removing power of course won’t stop it. That’s why the battery capacitor is there. I am so used to it stopping that I had forgotten! It’s my reflex to this kind of situation, built up over several years: press the STOP STOP button. I have to unlearn it. Especially since it also works for my other MS2, the one that controls the H0 /HO models.

Next remedy was to add two felt pads (maybe not felt, this type has more elasticity to them, more like cushions or rubber) on each buffer plate. Press picture and zoom in. It would hopefully absorb some energy should any next time happen.

Then, even if I have experienced software crashes and restarts with version 3.55 of MS2 (but only on my HO layout, with protocols mixed), I think the problem here was that I had gotten so eager that I pulled the cable too much and the MS2 was unpowered for a short period. (But it changed language..) I could see the cables just getting in contact. (Which might explain the language change..) So I made a backplane for it and fastened the cables with cable ties. See picture. Update 1Nov2020: I have seen one language change (back to German) and one run-wild uncontrolled situation (but thanks to the remedies below, with no consequence whatsoever) also after this change. No bad contact, that is. It’s something with the SW/HW of the MM2.

Setting Vmax

I then set lower max speed (to 40), lower acceleration delay (to 3) and and lower brake delay (to 3). Now I have more direct control with the loco, and it can’t speed up too much for any worst case buffer bumps. Here’s how:

-

- I am using a mains switch in the power supply to the rail box. I have described this in note 132 (here). This way I think the firmware of the MS2 is not (so often?) destroyed beyond update from another MS2 (in which case it has to go to Märklin service in Germany). The switch is seen in the picture here as well

- I let the MS2 stand «on» the locomotive and inserted its loco card. This reads the card and replaces any data set in the MS2

- CV 03 acceleration delay and CV 04 breaking delay I set the easiest way (method 1 (named by me)). Change loco, Acc – Dec etc. I set both values to 3, after experimenting some

- CV 05 maximum speed I was not not able to set by method 1 (well, it looked like it did, but the loco did not seem to accept it). Therefore I did method 2: Program CV, which causes it to read the Mfx registers etc. Motor, Speed, Vmax. This worked, and I set it to 40. However, for some reason method 1 had not caught up with the value. I wish I had been responsible for that software. I wouldn’t have been satisfied with this

- I then wrote to the loco card

Tacho value

By the way, what is the tacho value of method 2 (above)? It’s displayed as value 75. Does it have anything to do with the discussed Ticking? I cannot find anything about it in any of the documents [8], [11] or [26]

Setting direction

Fig.5 – MS2 arrows fit Märklin 55681 direction with DCC CV 29 BIT0 set accordingly. Photo Øyvind Teig (press for more pixels)

(Search: «SET-DCC-CV»). The arrows on the MS2 and the loco direction were opposite! And I did not want to turn the loco around, because (1) I wanted to see the driver in the I end, and (2) I want to see the electrical wires on the top – from where I normally stand. See märklin-users.net point 3, which is where I got the hint, here is how I did it:

- Starting with the loco registered as mfx+ and having a copy of its setup on an (orig) loco card

- I set the protocol to DCC only

- I deleted the loco

- I added a «Kroki DCC3» as my new loco, with address 3

- I changed CV address 29 value 0x06(=6) to 0x07(=7) to have the direction BIT0 set

- It worked, the arrows on the MS2 now point in the same direction as my loco on my 2 m. shelf track

- I saved the loco to another loco card

- I deleted the loco again, since I did not want to set all the icons etc.

- I added the loco back again from the (orig) mfx loco card

- I changed the protocol to all three: mfx,DCC,MM2

- The loco now runs mfx and the arrows on the MS2 are ok!

This is about the same procedure as How to set register CV 50 to value 8 with MS2 in note 132.

However, this may also be done when the loco is configured. This is explained in the 60657 MS2 booklet: Mobile Station 2 (version 3.55 or higher):

- P17: The following selection is only for locomotives with DCC decoders

- P18: Programming a Locomotive (CV)

Trivia

- «scale 1» = «1 scale» = «gauge 1» = «1 gauge» = «gauge one» ≈ 1/32 with..

- ..gauge = 44.45 mm → 45.0 mm Märklin, like 59059 (?)

Listed (1-5)

- When I had unboxed it and was going to clean up in the box, I found a loose plastic piece with a Swiss cross. It turned out to have fallen off the one of the joints of a rod. It was the cup, the one in the lower middle on the third driving axle of fig.1. I just pressed it in place, but I heard no click. So I must be observant in the future

- The wheels are driven through the external rods, no gears on the drive wheels, and one electrical motor in each bogie.

* At very low speed (creep range, close to stop or start, like when going from the last step to stop or from stop to the first step) the rotation is somewhat irregular and choppy. I think I heard said on the German language DVD accompanying [1] that the Ce 6/8 locos were famous for the sound of the rods, that they were somewhat loose in the joints. (Update: I have now discussed this more, see above). They certainly are somewhat loose on the model, so this is only natural. I have not changed the number of speed levels and the minimum speed in my Mobile Station 2. They are at default - Even though the very large proportion of pieces are of metal (mostly die-cast zinc, with some smaller parts from brass ([19], Longimanus), some are of plastic. Like the sanding tubes, and the inside of the doors. All the breaking arrangements as well. Plus the «excitation and reception magnets for train protection» at the center of the unit. (See Train protection systems Integra-Signum and ETM-S in this note). I guess this is just as good, plastic would not break as easily as cast metal. Also, the boards to walk on, on the top, appear to be plastic. The flexible cables connecting the parts, two sets on each side, are rubber or something very flexible. See my question at markin-users.net, here. My buying of the loco was dependent on exactly that answer

- Observe that the metal alloy is not magnetic, so it’s not possible to use a magnet to check what is what

Ticking

- The f30 sound is the «Speedometer (ticking)«. How does it work? It also ticks when the loco is standing still. See question 5 on marklin-users.net which you should read before this. I have also asked on Norwegian nmjforum.no at Mekanisk speedometer/tachometer anno 1920:

* I have recorded and measured the ticking. There is a distinct tick every 0.495.. second. I assume that is meant to be 0.500 second, but the clock in the loco which they recorded from may not have been tuned that accurately. Between this tick there are two smaller ticks, so we have three intervals. At 36 km/h anything moves 10 m per second (36000 m / 3600 seconds), 5 m over half a second. This is a little more than a revolution. The main wheel has a diameter (⌀) of 1.35 m, so it would move 1,35 * π = 4.24 m in a revolution. If the speedometer is being kicked once per revolution per second it should show 36 km/h * (4.24/10 ) = 15.26 km/h. Thus with a fast «up» / slow «down» arrow to integrate over this length it should show about 15 km/h. If the speedometer is a wound clock I assume the ticking is to clear the integration, hold the arrow or something like that. In that case it would tick while there is a stand still. Plus it should then show zero, to be verified by the driver.

* I found in [2] (p.20) that the speedometer of Ce 6/8 II was indeed Systems Hasler type. This was also suggested here:

* From question 5 on marklin-users.net there’s more (there may be more at the source):

Me: «I have been thinking, maybe the ticking at stand-still might be from a paper logging mechanism? I read that the clock logged events on paper from the Integra-Signum safety system.»Unholz: «Oh yes, this is certainly true. I remember the recording paper rolls in the Hasler speedometers from my youth when it was still easily possible to sit next to the driver/engineer or behind him in some SBB railcar types (namely the «Red Arrows», the BDe 4/4 and RBe 4/4). The paper had to be exchanged from time to time. I don’t remember whether this was after every driver shift change or when the direction changed or simply when the registration paper was full.

BTW, the registration paper was always removed and confiscated by the police immediately after every accident or derailment because it contained the necessary information about the speed of the train.»

Tom Jessop: «The Hasler recorders used a roll of waxed paper which recorded speed, engine notch position (speed setting), brake pipe pressure and brake operation, use of whistle, vigilance (dead man’s pedal) operation & something else which I cannot remember. Air pressure from different sensors then caused needles to operate across the waxed paper. A roll of paper would possibly last a month or more depending on locomotive use, the roll would be checked each time the engine would be prepped & if the tell tail on the tape was showing a fitter would be advised to come & put a new on in the recorder. Although a speedo is in every cab only one would have the tape facility mounted in it. This is only for double ended engines.»

* Worth reading is the Speedometer article at Wikipedia, but it did not make me any wiser in this regard. Or maybe even more interesting are the Tachometer or Wheel speed sensor articles. But to me, still unsolved how this one would work.

* I also discovered a Tacho value. What is it?

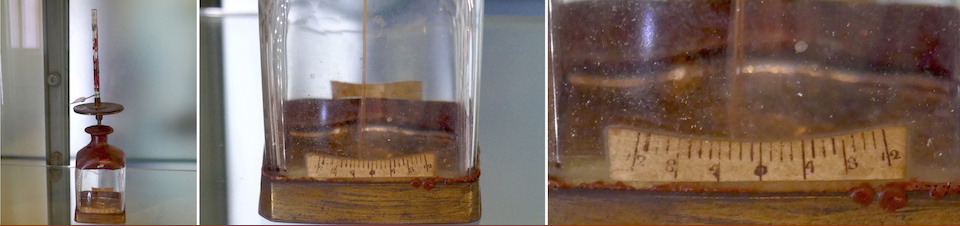

Speedometer with clock

Maybe the final solution is as simple as this? The picture here is taken from an article in the Neue Zürcher Zeitung [23] and shows the speedometer with 24-hour dial in the 14253. Of course this clock ticks! This is the first picture I have seen of it. In retrospect, in all but one of the other references up to [23] I cannot find it. Not even on those from the newer cabin, like the double page picture of the 14253 (page 34-35) in [2]. The reason is simple. On the picture from [23] there is a different speedometer! It simply does not have a clock. Looking over the movie that came with the [1] DVD (example at 1.20.04) the clocked speedometer is seen in the 45 degrees right side window.

Maybe the final solution is as simple as this? The picture here is taken from an article in the Neue Zürcher Zeitung [23] and shows the speedometer with 24-hour dial in the 14253. Of course this clock ticks! This is the first picture I have seen of it. In retrospect, in all but one of the other references up to [23] I cannot find it. Not even on those from the newer cabin, like the double page picture of the 14253 (page 34-35) in [2]. The reason is simple. On the picture from [23] there is a different speedometer! It simply does not have a clock. Looking over the movie that came with the [1] DVD (example at 1.20.04) the clocked speedometer is seen in the 45 degrees right side window.

Update 15Jun2020: There also are two great pictures at [24] (Cab rides, Führerstandsfahrten by SBB Historic). See picture 3 and 5 of the 14305 series. Also, picture 3 shows the cabin in wide screen. And picture 5 shows the bottom text of the instrument:

HASLER A. - G. BERN VORM. TELEGRAPHENWERKSTÄTTE VON G. HASLER

Speedometer without clock

And the Märklin 55681 cabin of the 14305 has a speedometer just like on the picture in [23] – without any clock! Is this also just a left out detail (like the dead man’s pedal, below)?

So there still is a mystery: what ticks, then? Is it still the paper logging mechanism?

From which locomotive is the soundtrack of the Märklin 55681? 14253 of 14305 or even 13302?

Clock & speedometer with recorder on the top

The pictures that I shown here (and above) have something on the top of the speedometer & clock unit. But I didn’t really discover it before I had the very nice book [12] in my hands («Krokodil» by Zellweger of SBB Historic). On page 79 there is a driver that runs a Crocodile, it must be before 2005. I assume the top box is the one that used to have the waxed paper, and that the vertical bars are the writing mechanisms(?)

Details of speedometer of SBB Ce 6/8 from magazine photos. Left: (1930?) [2] p17 SBB. Center: Ce 6/8 III [1] p47 2019? Eckert? Right: 14305 [1] p41 2019? Bloem

There are more photos of the speedometer box. I have collected all of the others I have in July 2020. One from about 1930 and two from 2019, I assume. Those from 2019 may be from 2000 for all I know, but they are of newer date. On the center picture the top box is gone. Is it being serviced or has it been removed for good?

Aside: I scanned these pictures at 1200 dpi. All of the rasterisation from the printing process was visible. Not nice to show. I tried all the filters I had, but since I was only going to get my point across, pixels were not so important, but some clarity was. And they are anyhow owned by the photographers, so I must be careful about copyright. (But every time I ask I get a «go on», so I assume it’s ok.) I scaled down to 900 and lost much of the picture. And then up to 1800. Quite a nice home made filter to remove at least som rasterisation. Scanning at 100, 300 or 600 dpi in the first place did not do the trick. I did not end up with as nice(?) pictures as these. Even if it they are not there for the pixels, it doesn’t hurt that I honour the originals.

Time off for a picture

Listed (6..)

- After some time I discovered that a cable at the roof was not in position. This is visible in Fig.1 (right door, left handle then up, the purple cable end). The photo is not in focus there. When I moved it slowly with my fingers I was able to press the cable up and into its two fastening holes. I am 90% certain that this was as arriving in the box

- The labels on the servos for the pantograph don’t stick! Lift off the roof to see. I made new paper labels that I fastened with double-sided tape that I know stick. And stored the original stickers. If you want to do the same, print out this PDF

- The layout of the two central fan frame blinds may not be as prototypical as they could have been. Disclaimer about this: I am quite unsure! See note 203: Fig.1 aside

- Spring-loaded axles

* On the Märklin 55681 with the three driven axles on each end part, the central axle only is spring-loaded. This makes 90% sense. Passing over a bump – that axle will be pushed up. Passing a dip it will be pressed down. But the two other axles on that bogie might, on bad track, be pressed up from the track, since they don’t follow. However, even if the model costs a lot, spring-loading all the three driving axles would have added cost. I am ok with not having to carry that extra sum, and instead keep my track from becoming bad. It looks like the 55681 certainly runs very smooth. More: it is a dream come true to hear, feel and see it run! Even without engine sound

* This is somewhat different from the Ae 3/6 II HO Lemaco model I have, which is spring loaded on all three powered axles. In this case the locomotive probably will follow coarser track better than my 55681. For the Lemaco, see SBB Ae 3/6 II (Spring-loaded Lemaco model)

* The two pilot/leading wheels in each end are of course spring loaded on the model

* The real locomotive has leaf springs on all axles, even an intricate system with some springs being interconnected. When I turned my 55681 upside down, to see if this were modelled (when the top fell off!) I could see that Märklin seems to have modelled the complete spring system. Have a look at the beautiful pictures in [19] by Longimanus - All the 18 Ce 6/ III were originally painted in brown colour and black chassis ([2] p.61). When was the #14305 (and #13302) painted in the fir-green SBB standard color and with gray-colored bases and drive parts?

- 55681 has no traction tires, and they are not needed. Much nicer without them!

- I have not found any materials and an exploded drawing of the 55681. There are some necessary drawings in the manual that comes in the box [8]. Would have been very nice to see them!

- Since the Märklin 55618 is revision

02.11.17(2017) the colour (color) scheme should be as the original was at that time. Tinu (24Jul2019) [19] mentions that Märklin shall have stated that it is painted as it was on date of issue (2019), where the real handrails are black. But they were, according to Tinu yellow before they were painted black, in Jan2018. Consequently they were in fact yellow, as on the model, on the printed revision date02.11.17. However, I would assume that when he says that the main green is not 100%, that might be correct. Because the green does not seem to have been painted in Jan2018 - I got this in a mail from a German friend, talking about the new Märklin scale 1 models (KM1 = KM-1 = KM-1):

«Märklin went with the production from Hungary to China and choose the producer of KM1. So they have absolute new know how and cheaper prices. The new models by Märklin look same as Kiss or KM1. But they are mostly die cast, which is not bad for players.»

What applies to the 55681? I have not spotted any «Made in ..» on the model, box or in any manual - The nicest picture you will find of the 55681 is on the box! However, it is only the right side of the loco (when end

Iis ahead). I think the two pictures on the longer sides (52.6mm long buffer-buffer) are the correct ones. The one on the long top is a little pressed down, so it looks a little flatter than it is (I think). There also is a similar, small one at one end. I think it’s ok. Märklin must have had both sides of the loco photographed? In case, why didn’t they print both? And why did they print the least sexy side, with so few cables on the roof seen? Ask me, who only realised the same point after my wife shot the picture!

Rods, axles and ends

(Thanks, Eiler, for trigging me on these points!)

Rod placements

On my model, in both end I and end II, it looks like the rod placements are about 87° out of angle, one side of the locomotive with respect to the other side.

In the figure I have measured the angles from zero in the running/rotating directions “ahead” and “reverse”. I run ahead (white graphics) in the I direction and reverse (yellow graphics) in the II direction. There are 13 spikes, so each angle spans a «spike angle» of 360°/13 ≈ 27.69°. For the front end I I got 87.8° displacement. For the back end II I got 86.5° displacement. Like about 87°. But it’s not very accurate. If this should have been 90°, below is what 3° looks like. Yes, I may have been that wrong!

I don’t see that 87° coincides with spike angle or multiples of it, like 27.69° * 3 ≈ 83.08°. Maybe it’s more a function of the internal gear construction in the Märklin model?

How is this on the real Ce 6/8 III #14305? Will the rod placement angle have any significance on how smoothly the locomotive runs?

Axles

All the eight axles have their two wheels shrunk on them. Therefore two wheels and their axle are one part. As we have discussed a lot, the driving wheels on each side have rods connect their three wheels with the countershaft («Vorgelegewelle»).

Two motors are paralleled. Each just have to have a through-going axle. We can actually see them on the outside: the two half moons. On each end of the axle there is a small cogwheel connected to the larger cogwheel on the countershaft. This forms a gear on each side with a 4.03 : 1 ratio. So there would be four such gears on the locomotive.

I am not certain whether the countershafts have a single connecting axle or if they are alone on each side. I only found one picture out of all the ones I have (scanned from [2] p.19 and cropped to a small fraction only). Speculating (seen in the picture as red), I think I can see that there is an axle between the countershafts: a common countershaft axle and a gear on each side. So «everything» seems to be mechanically paralleled. This is something that everybody that knows just a little about this would know. Help!

I am not certain whether the below indicates the opposite, that the countershaft gears are held in place «locally», with no connection to the other side. See [2], page 16:

| Die Bewegung wird auf die im Rahmen fest gelagerte Vorgelegewelle mittels beidseitig angeordneter Zahnräder in einfacher Übersetzung von 4,03 : 1 übertragen. | The movement is transmitted to the countershaft fixed in the frame by means of gearwheels arranged on both sides in a simple ratio of 4.03: 1. |

By the way, the Coupling rod, Jackshaft and Stangenantrieb articles are interesting, see Wiki-refs.

Ends

There is no mechanical connection between end I and end II, no synchronisation. Even if all four motors are powered from the same transformer with the same step and all four motors are AC single-phase motors. (See SBB Historic: Schaltplan – two circuit diagrams of the Ce 6/8 III crocodile.) Speculating again, having them synchronised would make pulling less efficient. If one bogie’s wheel-set were to slide, the other bogie’s wheels could take over.

Artefact sound?

Update: I also hear this sound of a phantom raising of a pantograph if the f30 speedomer ticking is activate when the loco gets power for the first time. Before this activate f30 only and unpower and wait until the power bank is empty and it stops ticking.

Strange artefact sound on first start-up. Listen to it here. There is one strange sound (?), a start, a stop and a start again:

The sound file is downloadable from here. I recorded it on an iPhone.

When I repeat start-up (operating sound: f2) and turn off and new start-up I don’t hear the strange sound that comes before the first f2. When i press the STOP button on my MS2 and wait some seconds and power the line again, and then a new f2 to start, this artefact of a sound comes. Have Märklin hit the wrong seconds tag on the sound file? (If that is how it works).

In the manual f2 is said to be «with random sounds». I assume that the random generator that is used in the firmware is a pseudorandom number generator that starts with the same seed. Then the sequence will be the same for every locomotive, every time. May this artefact sound be a feature from this effect?

I have tried all the sounds available on the loco, and I cannot find that artefact sound. I think it is the sound that comes when raising a pantograph.

I have queried about this at marklin-users.net, point 4 (below).

The original sound file is downloadable from the Sound-/Decoderproject at the 55681 page [9]. It comes down as M55681_Ce6-8-III-Historic_Spur1.mdtp. There is a tool to build these files called mDecoderTool mDT3 [10]. Which decoder does the 55681 have?

Multi-stop station announcements

The 55681 has multi-stop station announcements (on repeated f27), given in sequence (starting on the last used, respection direction change – if the DCC register CV 60 has default value). Here are the 11 stations. They are announced in Swiss, on 3 and 4 especially difficult to understand:

- Erstfeld (60.53 km from start at 475 m above sea level)

- Amsteg

Also called Silenen Amsteg - Gurtnellen

- Wassen

- Göschenen (1109 m)

Gotthard rail tunnel here. 15003 meter long at 1154 m maximum inside, opened in 1882

- Airolo (1144 m)

Ambri Piotta not stopped at

Rodi Fiesso not stopped at - Faido

- Lavorgo

Giornico not stopped at - Bodio

- Biasca

Osognia not stopped at - Bellinzona (169.62 km from start at 244 m)

Driving distance is 109 km and maximum elevation is on the southern side, where it is 910 m. Maximum elevation is 27 ‰. Distances from start is taken from the Timetable of Gotthard Railway from 1899 (GOTTHARDBAHN Fahrplan v.1.October 1899) on Wikipedia (here) referenced in the Gotthard railway article. The heights are from the same article’s figure, Longitudinal profile of Gotthardbahn incl. branchlines. The «not stopped at» info is deducted from table Gotthard Railway Double Track, also in the same article.

Q1. I don’t know why 55681 does not stop on all stations. Maybe a limit to the size of the sound file or didn’t the original stop on them? Here it the answer from SBB Historic’s JC, when I asked:

I must admit that I do find the multi-stop announcements a bit confusing – seeing how the Ce 6/8s were built as freight locomotives, it makes little sense for them to have stop announcements.

In the mid-fifties, when their designation changed from Ce to Be (meaning it had a higher maximum speed and was thus also suitable for passenger trains (where it would make sense to actually have announcements)) they did apparently pull some passenger trains over the Gotthard. I did however check with a timetable from Summer 1955, but none of the trains had that exact stop pattern. (Maybe that one is on the sound effect producers?)

Or maybe it boils down to having fun and informing me about some of the stations, of which I have sadly visited none. Like saying: «you should go!» Plus, I guess they do have some museum traffic with passengers these days… So, yes, I should go.

Q2. Also, why do they have a local maximum height inside the tunnel? Maybo so that they in case of power failure always could roll towards one of the ends? Update: wrong! Here is why (thanks, JC):

As to your second question, this is apparently for water drainage reasons (and air circulation)! I have attached a scan from a book on tunnels from 1920 [33], it says «lange Scheiteltunnel unter Gebirgsrücken erhalten aus diesem Grunde meist Fall nach beiden Seiten» (long summit tunnels below mountain ranges usually receive a decline towards both sides), listing the Gotthard as an example.

Train protection systems Integra-Signum and ETM-S

Summary: Integra-Signum unfolds as the excitation and reception magnets, down towards the track, in the middle of these locos. As seen above, the Integra-Signum is Swiss. It was in use from 1933 to 2018. Lately the newer ETM-S system was added, as a simplified version of the newer European ZUB standard. I don’t know if the crocodiles can run on all tracks in Switzerland these days.The «fitnessfahrten» are probably rather local. In the DVD accompanying [1] I think they said something about this, showing another, approved locomotive driving in front. I think that locomotive had ETCS Level 1 Limited Supervision (ETCS) system. Here is my path to this info:

I found this also confirmed in [2], page 45:

| Ab den 1930er Jahren war dank einer neuen Sicherheitssteuerung und der automatischen Zugsicherung die einmännige Bedienung möglich. | From the 1930s, one-man operation was possible thanks to a new safety control system and automatic train protection. |

Is the «new safety control system» the Integra-Signum safety system – that is seen visually by the magnets going down from the Ce 6/8 II and III towards the rails, at the center of the locomotive? Yes! By reading further in [2], page 62 I learn that:

| Die beiden Lokomotiven sind mit dem inzwischen vorgeschriebenen Zugsicherungssystem ETM-S ausgerüstet und gelegentlich vor historischen Zügen in derganzen Schweiz zu sehen. | The two locomotives are equipped with the now mandatory train protection system ETM-S and can occasionally be seen in front of historical trains throughout Switzerland. |

That text is in a chapter about the III-version locos. Therefore the two locomotives referred to are the two green coloured locos (1-2). Did the brown II-version (3) also get ETM-S added to its original Integra-Signum system?

Then, in the German Wikipedia article about Integra-Signum (chapter Euro-Signum) I read:

| Zum Lesen der Euro-Signum- und Euro-ZUB-Telegramme wurden bis 2005[3] die Streckentriebfahrzeuge mit einem speziellen Zusatzgerät, dem Eurobalise Transmission Module (ETM) ausgerüstet. Das ETM, umgangssprachlich auch „Rucksack“ genannt, leitet die Informationen an die Integra-Signum- und ZUB-Fahrzeuggeräte weiter.

Zunächst waren noch etwa 400 Fahrzeuge des Rangier- und Baudienstes von der Umrüstung ausgenommen.[3] Fahrzeuge des Rangier- und Baudienstes oder historische Fahrzeuge, die nicht mit ZUB ausgerüstet werden mussten, wurden bis 2011 mit dem vereinfachten ETM-S ausgerüstet, das sich auf die Integra-Signum-Funktionen beschränkte. |

Up to 2005, the mainline vehicles were equipped with a special additional device, the Eurobalise Transmission Module (ETM), for reading the Euro Signum and Euro ZUB telegrams. The ETM, also known colloquially as «backpack», forwards the information to the Integra Signum and ZUB vehicle devices.

Initially about 400 shunting and construction vehicles were excluded from the retrofitting. [3] Shunting and construction vehicles or historical vehicles that did not have to be equipped with ZUB were equipped with the simplified ETM-S until 2011, which was limited to the Integra Signum functions. |

Vehicles that were not equipped with ZUB were equipped with the simplified ETM-S. Von Plutowiki – Eigenes Werk, CC BY-SA 3.0, Link

«An Eurobalise is a specific variant of a balise being a transponder placed between the rails of a railway.» See Wiki-refs.

From the German Wikipedia figure we can see the Integra-Signum magnets. See Wiki-refs, both German and its translation, and the English version of Integra-Signum articles.

Driver in direction II and a ground personnel

Also see:

- 229:[Fitting the drivers] – of the Fine Models E71

- 216:[Height of scale 1 figures]

The 55681 model is not really sold as being able to drive more than ahead in the end I direction, is it? Reason: there is no extra driver in the end II cab! I intended to fill it with a driver, but it wasn’t as easy as I had thought.

Googling and then mailing around, I finally ended up with two choices. I ended up with both. I thought that i did not not want the spare lokführer Märklin E320244 that’s already driving in the I direction. Two reasons. I didn’t want them to look like identical twin brothers and I wanted to be able to open the door fully inwards. Märklin sent me a E602430 as a Christmas gift or whatever (thanks!) (the only exception so far to my Standard disclaimer), but it would have to wave his right arm out of the window (which would have been nice!). Since that’s not possible he was transformed to become my first ground personnel!

Fine Models insisted that I got a Swiss driver! I’m not sure if the one they found for me has a part number. He wasn’t really able to do the driving with his hands on the controls, but as seen from the outside it’s more than good enough!

The two men would have been about 160 cm and 167 cm tall. The head space in the cabin is about 58.5 mm * 32 = 187 cm. The door opening is 54 mm * 32 = 173 cm. When the men are seen compared to the locomotive it’s striking how huge the loco is! I’m looking forwards to seeing it some day!

The built-in man probably is glued in place. And the door does not fully open. I reckon that it’s like this in the real cab: it’s not a dancing floor. At the beginning I tried to find out how to remove the center box, so it would be easier to fit the driver down from the top. (It’s in Don’t loosen the center box (above)). None of my drivers have been glued in place. Quoting myself from the E71 note: «Yes I know, the fitted driver on the Märklin 55681 is glued to the floor. But none of those drivers fitted by me will be glued. What happens when somebody is just a little too curious – with the floor? I couldn’t bear the thought of it.»

I ended up with keyhole surgery, or rather zero invasive surgery, and tweezers (with plastic on the tips!). I decided not to glue it there. I wouldn’t want to (later) make scars on the floor and I assumed that if the door were to be opened, some small fingers may just go in there for an innocent check. «Oops!!»

To keep the door held open during all of this process I took some dental floss, a piece of soft plastic, bored a hole in it, and fastened it to the end. Then sowed the floss through the opening to the left, with the door open, the floss all the way alomst to the other door, there’s detail there that it can hang on and then down, with something soft pulling it down (the yellow piece in the picture). The piece at the end, inside the cabin, holds the door open.

To keep the door held open during all of this process I took some dental floss, a piece of soft plastic, bored a hole in it, and fastened it to the end. Then sowed the floss through the opening to the left, with the door open, the floss all the way alomst to the other door, there’s detail there that it can hang on and then down, with something soft pulling it down (the yellow piece in the picture). The piece at the end, inside the cabin, holds the door open.

I ended up, for the figures, with a plate to stand on. First cut from a tin box, but I didn’t like the appearance. I found a nice copper plate with glass fibre plastic inside. It’s 0.5 mm thick and it’s noted BENDFLEX on it, from the guys I once worked with at production at Autronica. Perfect! I made two straps of some 0.65 mm copper wire, bored holes and soldered them on. The size of the plate is 15 * 26 mm, and it must first be placed in the lower left corner and then slipped down towards the control desk. In Fig.36, see the small piece in front where I cut out a part, to make it pass the handle of the control desk. I made two such plates, because the hands at first collided with the desk. But the second around (actually the third) was fast finished.

I made some grooves in the plate to make it look like planks and painted it some (bad match, only seen when the door is opened, though).

Now I inserted the plate carefully, then slipped the man in and pushed his left foot first into its strap, then the right foot. This can be dismantled about as easily, with right foot first, even if I put half a drop of paper glue behind one shoe. The man stands quite sturdy in there. He’s loose, but still seems to sit stand quite in place.

Maybe Märklin should have supplied a driver for the end II direction, with the door also to be possible to open? He’d have to have a long right arm or do something else on the control desk. Like mine.. I’m sure they could find a smart solution for people to be able to insert themselves..?

Update 26Jul2021: I found that ASOA [34] carry a lot of figures! Like, search for «Krokodil» there.

Limits to miniaturization

Following up the chapter about the fact that there is no dead man’s floor pedal on my Märklin 55681, this chapter is relevant only as seen from a more general angle. Which is how I meant it in the first place. Here is my suggestion of an answer of why Märklin may have dropped it. It is still a model. Not the real thing. The window wipers don’t move, even with the f29 wipers sound on. There is no sand in the sand boxes, and the tubes from the sand boxes aren’t tubes. So what? Again, it’s a model. Scaling things down is about reducing size, how to do it, what to let go and what to keep. Some detail may have been scaled down 32 to 1 if that made them visible enough, or sturdy enough. Some may have been scaled down a little less, some much more, so much that that they are gone from the model. But they scaled the cabin. What the cabin is. And from the outside, a dead man’s pedal wouldn’t really add much. Maybe it was never even decided by the company, but maybe it was a decision done inside a single head; nobody thought any more about it. Maybe ten years before this model, for another model, with another level of detail. Then that piece was reused. It wouldn’t have been very expensive to change or add it at this point in time. But even then the driver still cannot die. He is still a model. On the other side: I can. And I will enjoy this model for my forever. It is not impossible to scale down everything. That’s just how it is.

Problems

Dead man’s foot pedal

Update Jan2024. The newer Märklin 55683 (search for it here) has got the «Dead Man’s Switch» in place! Thanks Märklin!

Fig.4 – Driver’s cab in 1920 (MFO), Märklin 55681: Ce 6/8 III, 14305 SBB Historic, rev. 02.11.17. Photo: Øyvind Teig (iPhone Xr: Magnifier app). Right: the loco in Olten on 19.02.20. Photo: Justin Comps, SBB Historic (press for more pixels)

There is no dead man’s foot pedal on the floor, inside the cab. (So, on my small loco, no vigilance operation. Thanks, Tom Jessop at marklin-users.net, point 5, below). I discovered the discrepancy when watching the fantastic DVD that came with [1]. The pedal is also seen on #14305 (2011) in a picture on page 44 of [2]. At first I thought that the pedal had been removed on the revision 02.11.17, which is the Märklin 55681. Maybe it was not needed any more, when more safety (of some kind) had been added? I mailed SBB Historic and I got the picture to the right (above) back. Thanks a lot! #14305 right now! I added some light to the floor part where the pedal is, just below the black protection shelf, so the pedal may be easily seen. Märklin has not replicated the pedal for the 55681.

Here’s more to the story. [JC] of SBB Historic, told in a mail that she had discovered (referring to the rightmost picture (above)):

«a picture of the cabin from 1920 in the book «Krokodil: Königin der Elektrolokomotiven» [12]. There was no dead man’s foot pedal! The text beneath the picture says «The working space of the Kroki-driver, as pictured in a publication of the Maschinenfabrik Oerlikon 1920». The dead man’s pedal was not built in from the start – it was only added in the 30ies – according to the author of [12]. However it was on 15Jul1920 that the RhB (Rhätische Bahn, another Swiss rail company) decided to go from two drivers in the cabin to one, and then introduced the dead man’s pedal in their locomotives [13]. Their locos were also built by SLM (Maschinenfabrik Winterthur, for the mechanical parts) and MFO (Maschinenfabrik Oerlikon, for the electrical parts) – just like the SBB Ce 6/8 II and III. It then looks like the SBB must have kept two drivers in those locomotives for another some 10 years.»

Nearly no reuse of 55564 parts on 55681

I therefore speculated (wrongly, see below) that the faulty (but forgivable!?) cabin in my (1) 2019/2020 model of the Märklin 55681, Ce 6/8 III revision 02.11.17 (2017) (colour green), road number 14305 is a reuse of the cabin of the (2) 2013/2014 model of the Märklin 55564, Ce 6/8 II, revision 27.5.29 (1929) (brown), road number 14281. Assuming that there is no dead man’s pedal in the 2013/2014 model. Update: however, according to a mail reply from Märklin I am wrong:

Dear Mr. Teig, 55618 and 55564 are two totally different constructions. So nearly no part from 55564 is used at 55618. All parts are new designed. Sincerely yours, Your Maerklin Customer Service (5May2020)

| Following this logic, there should have been two drivers in the cabin.. | ..but this would also wrong as seen from the outside, since it’s a 02.11.17 revision. |

It’s not only a pedal

As this theme develops, more info is coming in. SBB Historic’s [JC] has again responded and sent me some more background information:

«Some speculation on my part as well : Since the RhB is a narrow-gauge railway with a comparatively much smaller route system, they may have tried out the one-driver system earlier.

I tried to find some reference on the one-driver-system at the SBB and found the newspaper clipping you can find attached (Gossauer Zeitung 30.1.1932). (Press picture for full article.)

It’s from January 1932, back when there was still quite a public discussion about the safety of the one-man system. According to this article, the first trials at SBB with just one driver only started in 1926. It further states that at the time it was written the personnel felt negatively about the one-person driving and that there are still routes where two-manning the locomotive is necessary for safety.

So, safety systems where continuously being built into more and more locomotives. This would need definitely more research (and maybe there is a nice reference in one of our books I am simply overlooking…) but it’d be reasonable to assume that until then, the Kroki had two drivers.

Only somehow related, but in the same year a bad collision took place near Lucerne (Wikipedia, translated , where two one-manned trains collided, which then lead to the introduction of a Swiss-wide train protection system, Integra-Signum (Wikipedia, translated).»